How the Italian luxury supply chain – for decades a symbol of craftsmanship and sophistication – is in the spotlight of worker exploitation

Recent news is once again shedding light on the exploitative practices in the luxury supply chain in Italy. This time in Prato, one of Italy’s key industrial fashion districts, officials found documented and undocumented Chinese and African migrant workers being subject to physical abuse, long working hours, and poverty wages ¹. They were producing and supplying high-end handbags to a French luxury brand, underscoring the vulnerability of major luxury brands in supply chain malfeasance even in advanced economies. And this is not the first time that luxury supply chains in Italy are in the spotlight.

In 2019, in southern Italy, local authorities raided a leather workshop connected to the local Mafia that employed dozens of undocumented workers allegedly making leather goods for some of Europe’s best-known luxury groups ². Workers, including a pregnant woman and two teenagers, were working under forced labor conditions. These unlawful and exploitative practices are inherently linked to health hazards.

In 2013, a fire sparked by an electrical short circuit engulfed a workshop in Tuscany, killing seven Chinese workers. In the aftermath of this tragedy, Italian officials deployed a massive inspection campaign – visiting more than 8,000 small and medium-sized mills and workshops. Of this effort, 93% of the inspected workplaces were found to be committing egregious safety-code violations – ranging from illegal dormitories to dangerously exposed wiring ³.

Why is Italy a key hotspot for exploitative practices?

A mix of poor public and private governance systems are fuelling exploitative practices in supply chains:

Weak local governance and poor labor law enforcement allow suppliers to produce goods in informal and unsafe conditions. This phenomenon is particularly pronounced in areas where organized crime syndicates fill the vacuum left by the State – providing employment opportunities in economically depressed areas by establishing illegal production operations, often below the radar of tax authorities or in hybrid black market conditions.

The implementation of (I) strict immigration policies which prevent the formalization of foreign migrant workers in the supply chain and of (II) labor reforms that increase the formalization, temporariness, and flexibility of the workforce, have created over the years a pool of vulnerable foreign and local workers, primed for exploitation by unscrupulous employers.

Irresponsible sourcing practices by buyers in the fashion industry – like exercising unreasonable time and cost pressures – often push manufacturers to have their backs to the wall, forcing them into unauthorized subcontracting and therefore significantly reducing supply chain and purchasing practice transparency, clouding the visibility over working conditions across the supply chain.

Today, most luxury brands with a supply footprint in Italy face significant risks of tainted products– with risks nestled both among their direct suppliers as well as further down the supply chain among small and medium subcontractors.

What can brands do to protect their workers and reputation?

In the words of Ferruccio Ferragamo, Italian luxury brands historically do business on a firm handshake and a look into the eye 4. However – the reality is that the demand for luxury goods has grown to USD 308B – three times the level that it was 20 years ago – putting significant pressure on local Italian suppliers. Luxury brands need to adopt innovative strategies to run effective programs to assess and reduce sourcing risk in their supply chain.

Map the supply chain: Most responsible sourcing programs focus on preventing and responding to labor exploitation risks among their direct suppliers – known as “tier 1” suppliers. However, many companies lack visibility into the hidden labor exploitation risks associated with the raw materials used to make their products (i.e., the lower tiers 2, 3, 4, and beyond suppliers to raw materials). Suppliers need to adopt end-to-end traceability systems – i.e., survey, mapping, or chain of custody systems – to map their full supply chain – from the raw material to the final goods producer.

Reduce the risk of subcontracting to third parties: ELEVATE data reports that in the past 5 years, 7% of audited suppliers in the Italian supply chain subcontracted orders to unknown third parties without the buyer’s authorization. Buyers should invest in building a solid and trustworthy relationship with the supplier base by upholding their business commitments and investing in long-term relationships. This includes assessing supplier production capacity, monitoring their production costs, and promoting an open and frank conversation regarding their production capacity and the need to subcontract orders to meet deadlines or price targets.

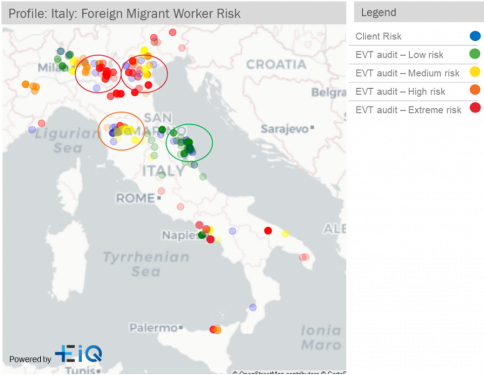

Adopt smart auditing systems: Integrating data and analytics into the audit planning systems allows buyers to dynamically prioritize their audit scheduling and choose more effective assessment methodologies based on the risk grading assigned to each supplier. For example, supplier self-assessment data, historical audits, and third-party information (news searches, web postings) can help gauge the initial supplier risk profile and determine whether it is best to conduct remote audits or roll out onsite assessments, or highlight the need for supplementary checks, like integrating foreign migrant worker risk assessments or production capacity verifications.

Fig.1 ELEVATE EiQ Platform provides insight on supply chain risk at the sub-national level – supporting the identification of high-risk sourcing clusters.

Effective Grievance Mechanisms: Effective reporting and grievance mechanisms are a key component in ensuring that workers can report unsafe or exploitative conditions without being targeted by their managers. Adequate reporting mechanisms are anonymous, easily accessible, and real-time – linking workers to buyers or third parties that can assess reported violations and initiate an alert or remediation process. However, an analysis of ELEVATE audits collected in the past five years shows that 24% of the workplaces in Italy do not have adequate reporting mechanisms. These numbers are significant not only when compared to other developed economies like Germany or the United States – but are also 3 or 4 times higher than in countries like Bangladesh, India, Vietnam, or Myanmar.

An accessible, transparent, and trusted channel for worker voices to be heard can help create lasting connections and strengthen relationships between workers/employers and suppliers/companies and strengthen the supply chain itself, making it more resilient. And a resilient supply chain is paramount for business success in times of global instability.

ELEVATE is the leading business risk and sustainability solutions provider that helps companies map and evaluate their supply chain resilience, enabling the integration of worker voice technology, and designing data-informed responsible sourcing practices. Contact ELEVATE for more information on how we can support your business.

[1] Il Tirreno, Prato, schiavi per le borse firmate: pagati tre euro all’ora e botte se sbagliavano: March 2021 https://iltirreno.gelocal.it/regione/toscana/2021/05/19/news/pagati-tre-euro-all-ora-e-botte-se-sbagliavano-1.40290447

[2] Il Mattino, Lavoro nero, operai segregati in fabbrica nel Napoletano: il giudice conferma gli arresti, December 2019 – https://www.ilmattino.it/napoli/cronaca/lavoro_nero_operai_segregati_fabbrica_melito-4907176.html

[3] BBC, Italy Prato fire kills seven in Chinese-owned factory, December 2013 – https://www.bbc.com/news/world-europe-25180500

[4] SCMP, Business on a handshake fits Ferragamo just fine – www.scmp.com/article/991261/business-handshake-fits-ferragamo-just-fine

These blogs are written by ELEVATE staff members or associates and the views and opinions expressed are not necessarily those of ELEVATE.

About the author